| Bonding Rubber To Metal |

|

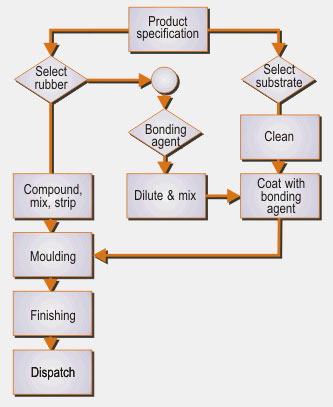

Rocket Polymers is recognized as an industry leader in bonding rubber to various metal substrates. We work with many types of rubber depending upon the specific product application. The selection of the polymer base and its related compound depends on the type of metal (aluminum, brass, bronze, steel, etc.) used to fabricate your product. In addition, certain characteristics that may be required to protect your product from abrasion and/or water, for example, are taken into consideration. For instance, the elasticity of the rubber is taken into consideration depending on the shape and size of the metal product – steel and aluminum alloys, such as brass and bronze.

Our bonding agents are comprised of polymer/solvent solutions and primer coats related to phenolic-style resins. A topcoat of polymers and other materials may also be utilized. |

|

To ensure the quality of the chemical or mechanical bond, several steps are taken to prepare the metal surface to which the rubber must adhere, including:

- Degreasing and cleaning the surface

- Sandblasting or bead blasting the surface

- Chemical etching to dissolve the material’s surface

Once the surface is prepared, a bonding agent or adhesive is then applied which results in a bond that is physically stronger than the material. Therefore, the rubber will tear before the bond fails.

Rocket Polymers utilizes three types of rubber molding, including:

- Compression molding

- Injection molding

- Transfer molding

The production volume related to your product will determine which molding process is best suited for your application.

Over the years, we have focused on a variety of industries for which we have manufactured rubber products made from bonding rubber to metal, including:

- Electrical (rubber insulators)

- Power transmission

- Vibration isolation (rubber pads) and containment

- Various types of silicone gaskets

- Bumpers

- Plumbing supplies (rubber caps and plugs, fire hydrant seals)

To speak to a rubber molding specialist, please contact us or call us at 314.533.9200.

|